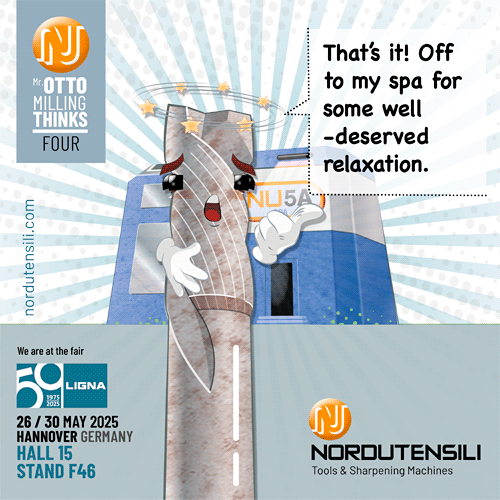

NU5A is a totally automatic sharpening machine, patented by Nordutensili Srl and specifically designed for tungsten carbide and HSS tools.

The NU5A technology allows the characteristics of the cutting edges and tool angles to be automatically collected by the software through a laser and therefore it is easy to verify the geometries of the tool to be re-sharpened. Another advantage is that the machine does not require specialized operators on board the machine because the NU5A software can switch from the recognition and regrinding of one tool to another without the intervention of man. For this reason teaching courses of how to use the machine require little time.

This 5-axis sharpening machine guarantees high production with minimal energy consumption and air-oil lubrication allowing to limit the environmental impact.

The NU5A software automatically warns about ordinary operations (measuring wheels, grinding wheels, …) and automatic procedures allow you to check and compensate for the shape of the wheels. Skilled operator could adjust the geometry of tool, if necessary, always assisted by software that automatically prevents any error and avoids the collision between the tool and the grinding wheel.

Its compact size allows easy and trouble-free installation, making it a machine suitable for any sharpening center as it takes up little space and the staff can let the sharpening machine work independently and optimize their time.

Software features:

Control type CNC, automatic

Other characteristics

Software

Analysis Functions

Machining

Milling Cutters Supported

Sharpening Head

Motorised Axes

Dimensions

Weight

Lubrication

Electricity